Friction Welding

Overview

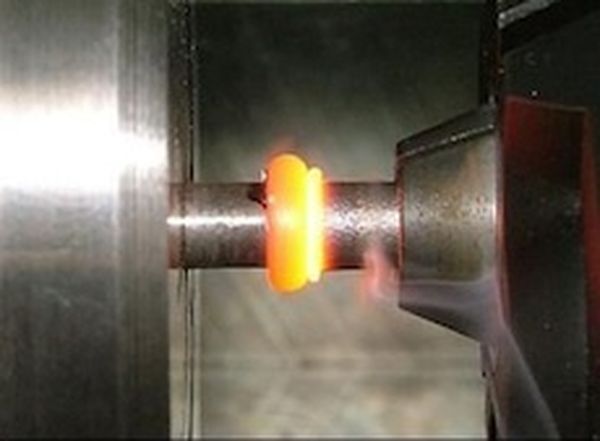

Friction welding is a bonding process that produces high integrity, full contact joints. By rotating one work piece relative to another, whilst under a compressive force, the friction generated between the two surfaces produces heat, causing the material to plasticise that creates a homogeneous bond between the materials. With friction welding, no third party filler materials, flux or shielding gases are required. There are four primary processes: Friction stir welding (FSW), friction stir spot welding (FSSW), linear friction welding (LFW) and rotary friction welding (RFW).

Tags

-

No tags applied

Developed by

KUKA Laboratories GmbH